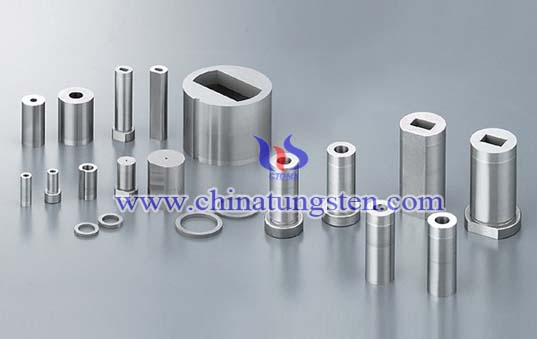

ทังสเตนอลูมิเนียมหลอมอัดรีด

ลวดเหล็กแข็งทำโดยทั่วไปโดยการบังคับให้โลหะแข็งผ่านรูที่เรียกว่าตายภายใต้ความกดดันที่รุนแรงเช่นนั้นจะถูกอัดเช่นพาสต้า คุณสามารถจินตนาการแรงเหลือเชื่อที่ต้องทำหน้าที่ในหลุม? ในบางกรณีเพชรหรือแซฟไฟร์ (เกือบแข็ง) ตายใช้ แต่คนนี้ทำจากโลหะผสมทังสเตนอาจเป็นเพราะความแข็งแรงสูงแม้ในอุณหภูมิสูงมาก

โลหะผสมทังสเตน (WHA) เป็นวัสดุที่เหมาะสมสำหรับโทลเวย์เช่นแม่พิมพ์อัดขึ้นรูปชิ้นส่วนหล่อตาย ฯลฯ โดยเฉพาะอย่างยิ่งเมื่อใช้ในงานกัดตายของทองแดง โลหะผสมที่เกี่ยวข้องกับการผลิตอลูมิเนียมสังกะสีและทองแดง castings.Tungsten อัลลอยด์การประยุกต์ใช้ตายอัดขึ้นรูปที่ทำจากวัสดุเผาประกอบด้วย Mo และ / หรือ W ที่มี 2-60% โดยปริมาตรของจุดหลอมเหลวสูงองค์ประกอบที่ไม่ใช่โลหะที่ปราศจากออกซิเจน (ยกเว้นอาจมีปริมาณไม่ดี)

มีคุณสมบัติอื่นสำหรับกระบอกโลหะผสมทังสเตนที่ทนทานซึ่งรับประกันอายุการใช้งานที่ยาวนานกว่าวัสดุตายตัวดั้งเดิมและมั่นใจได้ว่ารูพรุนที่หดตัวต่ำสุดของชิ้นส่วนหล่อตาย ดังนั้นการรีดขึ้นรูปที่ทำจากวัตถุดิบเช่นทังสเตนจึงสามารถใช้ได้กับการประกันคุณภาพและมาตรฐาน

ข้อได้เปรียบที่สำคัญของเครื่องอัดรีดโลหะผสมทังสเตนและชิ้นส่วนหล่อตาย: เสถียรภาพทางความร้อนสูงทนต่อแรงกระแทกได้ดีการแปรรูปที่ดีความต้านทานการแตกร้าวที่ดีเยี่ยมการลดเวลาในการกดลง