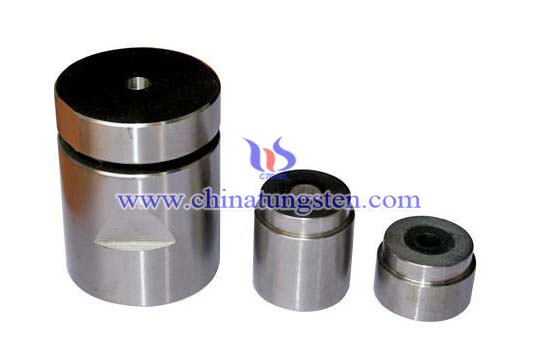

Tungsten Alloy Cylinder Extrusion Die

Tungsten alloy cylinder extrusion die is made of a predominant amount of molybdenum or tungsten, the remainder being zirconium. Extrusion die is usually used in the multiple extrusion process which is specially designed to prevent delaminating or cracking of the rods during extrusion.

Extrusion die is one of the forming techniques used in material processing, consisting of forcing the work pieces through a die, thereby reducing its cross section and increasing its length.Tungsten alloy cylinder is the popular used part of extrusion die because of its high melting point and corrosion resistance.

Major advantages of tungsten alloy extrusion die

High thermal stability

High impact resistance

Good machinability

Excellent crack resistance

Reduction in press down-time

Minimal extruded metal pick-up